AI Quality Prediction Model

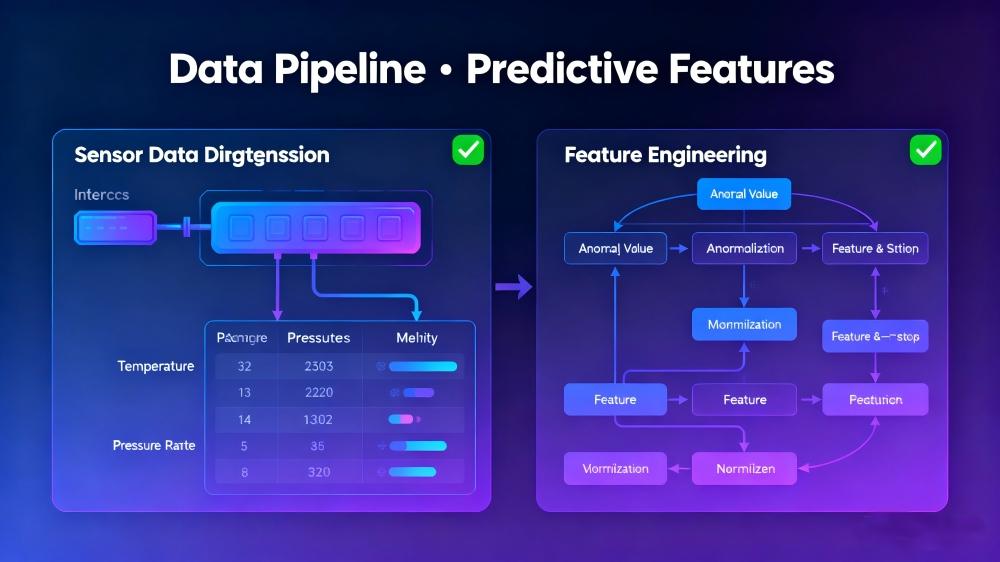

Gallop World IT’s AI Quality Prediction Model leverages Predictive Quality Analytics and Machine Learning for Quality Control to accurately forecast production quality risks and enable proactive control from the source. Integrating AI-Based Quality Inspection and AI Predictive Analytics Manufacturing, the system significantly enhances detection accuracy and efficiency while reducing human error. It helps enterprises build an end-to-end intelligent quality control system, facilitating a shift from post-production inspection to preemptive prediction and providing critical support for high-quality manufacturing.

- Information

At a critical juncture where manufacturing is undergoing intelligent and digital transformation, product quality has become a central element of corporate competitiveness. AI Quality Prediction Models, known for their accurate forecasting and efficient control, are now pivotal in advancing manufacturing quality. Specializing in enterprise digital transformation, Gallop World IT has extensive expertise in this field, supported by a profound understanding of industrial processes and a skilled AI team. We integrate Predictive Quality Analytics with Machine Learning for Quality Control, using large-scale production data to build AI models that identify potential quality risks early, thereby reducing defect rates at the source. Moreover, our AI-Based Quality Inspection systems streamline and automate detection, significantly enhancing accuracy and efficiency while providing reliable support for high-quality production.

Through years of innovation, Gallop World IT has delivered effective AI Quality Control Solutions to sectors including automotive, electronics, and machinery manufacturing, enabling a shift from reactive inspection to proactive prediction. Within AI Predictive Analytics Manufacturing, we design tailored models that suit specific industry needs—for instance, predicting strength and durability of auto parts using real-time material and environmental data, or assessing electrical performance in electronics to prevent faulty products from reaching the market. We continually refine our Machine Learning for Quality Control algorithms, adapting to dynamic production environments to maintain accuracy and relevance. This ensures that our AI Quality Control Solutions remain aligned with actual production demands, helping manufacturers build market trust through consistent quality.

Frequently Asked Questions

Q: We are an automotive engine parts production company. During our informatization development, traditional quality inspection methods struggle to detect internal hidden quality issues in parts in advance, leading to high rework costs after defective products are passed to downstream companies. We want to introduce an AI quality prediction model but are unsure how to proceed, and we don’t know how to enhance quality management capabilities through Predictive Quality Analytics and Machine Learning for Quality Control. How can this be resolved?

A: To address the challenges faced by your automotive engine parts production company, Gallop World IT offers end-to-end AI Quality Control Solutions. First, in introducing the AI quality prediction model, we will conduct an in-depth analysis of your production process, including raw material procurement, processing techniques, equipment operating parameters, and historical quality inspection data, to identify key quality indicators (such as internal structural integrity and material strength) for engine parts. Based on this data, we will build a dedicated AI quality prediction model. In the Predictive Quality Analytics phase, the model will collect various types of data during production in real time, using algorithms to identify abnormal factors that may lead to hidden quality issues—such as minor fluctuations in raw material composition or deviations in equipment operating parameters—and issue early warnings to help your company avoid quality risks before products are completed. For Machine Learning for Quality Control, we will use your historical defective product data to train the model, enabling it to continuously learn the features of different quality issues and gradually improve its accuracy in identifying hidden quality problems. At the same time, we will link machine learning quality control with production equipment control systems, allowing automatic adjustment of equipment parameters when the model predicts quality risks, enabling real-time quality control. Additionally, we will provide training for your team to help employees master model operation and data interpretation methods, ensuring the AI quality prediction model functions stably over the long term. This will thoroughly address the challenges of traditional quality inspection methods failing to detect hidden issues and high rework costs, while significantly enhancing your capabilities in Predictive Quality Analytics and Machine Learning for Quality Control.

Q: We are a consumer electronic device assembly company. During our informatization development, quality inspection in the product assembly stage relies on manual methods, which are inefficient and error-prone. We want to optimize quality management through AI-Based Quality Inspection and AI Predictive Analytics Manufacturing but are unsure how to integrate with our existing production systems and are concerned about the accuracy of model predictions. How can this be resolved?

A: Gallop World IT offers targeted solutions for your needs as a consumer electronic device assembly company. For implementing AI-Based Quality Inspection, we will deploy vision inspection equipment (such as high-definition cameras and industrial cameras) based on the characteristics of electronic device assembly to capture image data during the assembly process. We will then develop adapted AI-Based Quality Inspection algorithms capable of accurately identifying issues such as missing components, misassembly, and part damage during assembly. This approach improves inspection efficiency by 5–10 times compared to manual methods, with accuracy rates exceeding 99.8%. For integrating AI Predictive Analytics Manufacturing with your existing production systems, we provide standardized interface solutions to seamlessly connect the AI quality prediction model with your ERP and MES (Manufacturing Execution System) systems, enabling real-time data exchange. For example, the model can obtain production progress and equipment status data from assembly stations via the MES system, combine it with inspection data for comprehensive analysis, predict potential quality issues in subsequent production stages, and feed the predictions back to the ERP system to assist in adjusting production plans. To ensure the accuracy of model predictions, we employ a "data iterative optimization" mechanism, regularly collecting your actual production quality data to train and upgrade the AI Predictive Analytics Manufacturing model. We also implement a dual verification process, comparing model predictions with manual sampling results to continuously optimize algorithm parameters and improve prediction accuracy. Additionally, our AI Quality Control Solutions include a real-time monitoring platform, enabling your company to monitor AI-Based Quality Inspection results and AI Predictive Analytics Manufacturing data in real time, fully grasp product quality status, and completely eliminate the inefficiency and error-proneness of manual inspection.

Q: We are a large-scale mechanical equipment manufacturing enterprise. During our informatization development, the production process is complex and involves numerous types of parts, making it difficult for existing quality management methods to cover the entire process. We want to achieve full-process quality management through an AI quality prediction model but are unsure how to conduct Predictive Quality Analytics and lack the technical foundation for Machine Learning for Quality Control. How can this be resolved?

A: For the full-process quality management needs of a large-scale mechanical equipment manufacturing enterprise like yours, Gallop World IT will provide customized AI Quality Control Solutions. First, in conducting Predictive Quality Analytics, we will break down your mechanical equipment production process into key stages such as raw material processing, parts manufacturing, equipment assembly, and performance testing, developing dedicated predictive quality analysis plans for each stage. For example, in the raw material processing stage, we will analyze data such as chemical composition, processing temperature, and pressure to predict processing precision; in the equipment assembly stage, we will combine data such as part assembly gaps and bolt tightening torque to predict operational stability. At the same time, we will build a unified data collection platform to integrate production data from all stages, providing data support for full-process predictive quality analysis. In terms of building technical capabilities for Machine Learning for Quality Control, we will provide dual support through "technical training + on-site guidance." On one hand, we will offer training on machine learning for quality control technology, covering algorithm principles, model training, and data processing to help your team build a technical foundation. On the other hand, we will dispatch technical experts to provide on-site assistance, helping your company complete the deployment, debugging, and optimization of the AI quality prediction model, and guiding employees hands-on in operating the model to resolve technical issues in practical applications. Additionally, our AI Predictive Analytics Manufacturing model features a "full-process linkage" function: when a quality risk is predicted at one stage, it automatically triggers early warning mechanisms for upstream and downstream stages. For example, if a parts manufacturing stage predicts a quality issue with a certain component, it will promptly notify the equipment assembly stage to suspend using batches of that component, avoiding subsequent rework. Through this solution, your company can achieve full-process AI quality management for mechanical equipment production while quickly building technical capabilities in Machine Learning for Quality Control, driving your quality management capabilities to new heights.