Machine Vision Quality Inspection Solution

Gallop World IT's machine vision quality inspection solutions have been successfully applied in over ten industries, including food packaging, electronics manufacturing, and automotive components, serving more than 200 enterprises. Through innovative deep learning visual algorithms, our industrial vision inspection platform achieves a 99.8% defect recognition accuracy rate, with an inspection speed 15 times faster than traditional manual methods. These machine vision inspection systems support stable 7×24 operation and have helped clients improve inspection efficiency by 300%, building a comprehensive intelligent quality protection system.

- Information

As an innovative leader in the field of industrial vision inspection, Gallop World IT leverages its profound technical expertise and rich industry experience to provide enterprises with comprehensive machine vision inspection systems solutions. We specialize in developing AI-powered visual inspection technologies, utilizing deep learning algorithms and intelligent image processing systems to create reliable machine vision for manufacturing platforms for our industrial clients. Currently, our solutions have been successfully deployed across various sectors such as food, electronics, and automotive, assisting companies in achieving intelligent upgrades for quality control.

In terms of technological innovation, we continuously optimize our AI-powered visual inspection algorithms. Trained on massive datasets of industrial images, our systems possess exceptional defect identification capabilities. Our machine vision inspection systems support high-speed, precise part sorting machine vision functions and integrate vision-guided robotics (VGR) to automate production processes. These advanced technologies for machine vision for manufacturing help enterprises establish robust quality control systems, significantly enhancing production efficiency and product quality.

Frequently Asked Questions

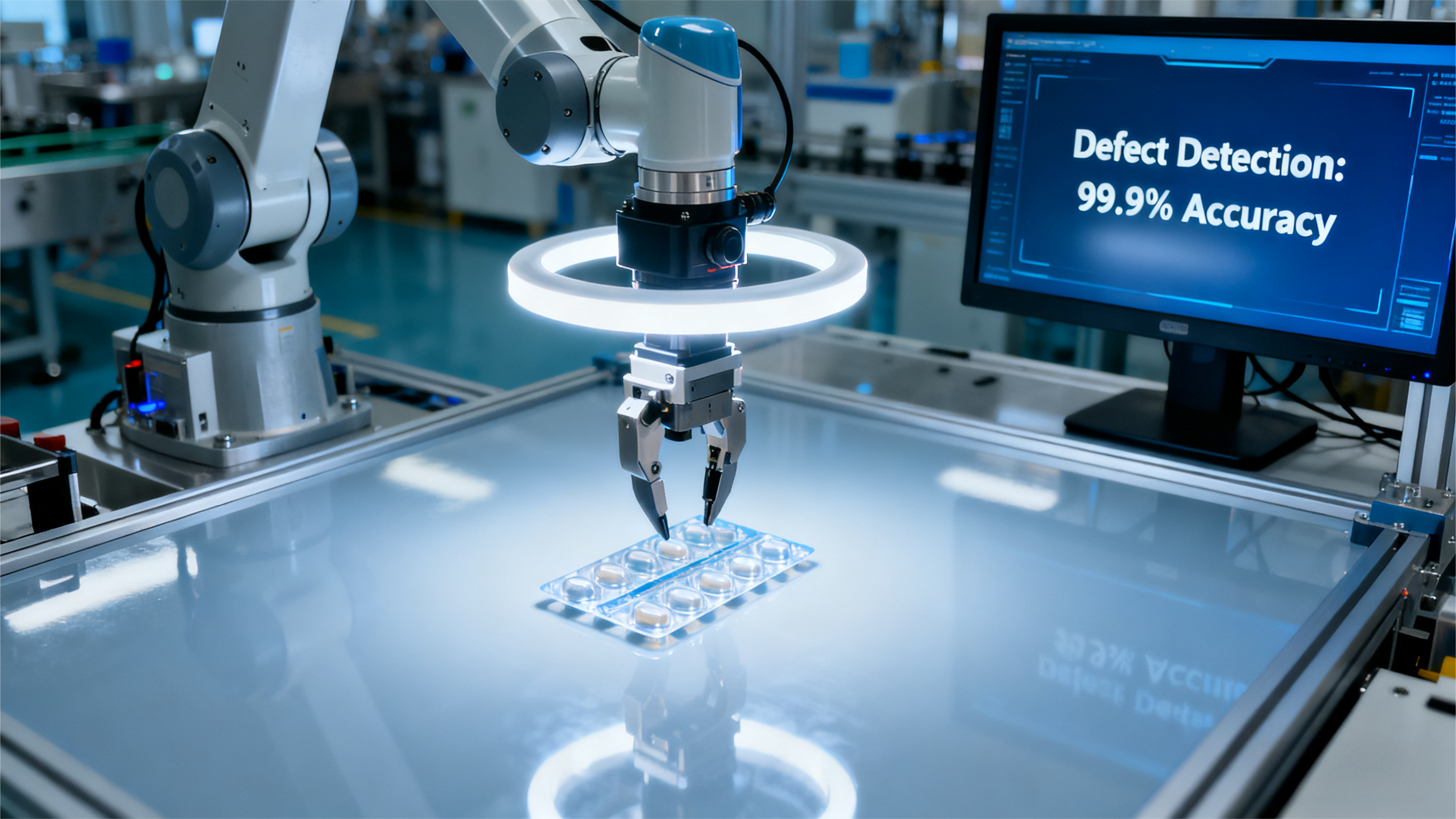

Q: We are a pharmaceutical packaging company needing to detect missing pills and misalignment in blister packs. Our current manual inspection is inefficient and prone to missed detections. Can your machine vision inspection systems solve this problem?

A: Our machine vision inspection systems designed specifically for the pharmaceutical industry are equipped with 5-megapixel high-speed industrial cameras and specialized lighting systems, enabling precise detection of defects like missing pills and misalignment in blister packs. Using AI-powered visual inspection technology, the system can identify issues such as missing or broken tablets within individual blisters in real-time, at speeds up to 400 blisters per minute. This solution for machine vision for manufacturing incorporates an advanced part sorting machine vision module with an accuracy rate exceeding 99.9%. Furthermore, the integrated vision-guided robotics (VGR) automatically reject defective products, ensuring a fully automated production process that fully complies with GMP standards.

Q: As a manufacturer of mobile phone components, we need to inspect the hole uniformity and surface defects of miniature speaker meshes. Our current equipment lacks sufficient detection precision, leading to significant customer complaints. What solution do you offer?

A: Our specially developed machine vision inspection systems utilize 20x optical zoom lenses combined with multi-angle ring light sources to clearly capture micron-level defects on miniature speaker meshes. Through AI-powered visual inspection algorithms, the system accurately identifies up to 25 types of quality issues, including hole deformation, blockages, and surface scratches. This system for machine vision for manufacturing features a high-precision part sorting machine vision module with sorting accuracy reaching ±0.005mm. The integrated vision-guided robotics (VGR), with six-axis functionality, perform precise grasping and sorting, operating stably even in Class 10,000 cleanrooms, effectively enhancing product quality.

Q: We are an aerospace components supplier requiring quality inspection and sorting of precision parts in high-standard cleanroom environments. Our existing equipment cannot meet aerospace-grade precision requirements. Can you provide a reliable solution?

A: Our custom-built machine vision inspection systems for the aerospace industry use aviation-grade materials and feature IP68 protection ratings, equipped with positive pressure dust prevention systems, fully meeting the specific environmental demands of aerospace manufacturing. Utilizing AI-powered visual inspection technology, the system can accurately measure critical indicators such as part dimensional tolerances (accuracy ±2μm) and surface roughness. This solution for machine vision for manufacturing includes a specialized part sorting machine vision module that achieves a 99.99% sorting accuracy rate while maintaining Class 100 cleanliness. The integrated vision-guided robotics (VGR) possess nano-level positioning capabilities and, combined with force control sensor systems, execute precise assembly tasks. This solution has been certified under the AS9100 Aerospace Quality Management System and has provided reliable quality assurance for numerous aerospace enterprises.